Mechanics Warn Against These Everyday Mistakes

Mechanics see the aftermath of shortcuts every day, and the patterns are unmistakable. Certain habits quietly chew through engines and brakes long before warning lights flash.

Drive On Tires Below 2/32" Tread Or With Visible Cords

Bald tires drastically reduce traction on wet or icy roads, which increases hydroplaning risk. Exposed cords further compromise tire integrity, often leading to blowouts at highway speeds. Mechanics routinely measure tread depth with gauges and recommend replacement well before legal limits.

PookieFugglestein, Wikimedia Commons

PookieFugglestein, Wikimedia Commons

Mix Random Coolants Or Top Up With Tap Water

Combining incompatible coolant types or diluting them with tap water introduces minerals that corrode aluminum components and clog small passages. Modern cooling systems rely on precise formulations to prevent galvanic reactions and maintain consistent boiling and freezing points. Professionals always use OEM-specified coolant or distilled water blends to preserve engine longevity.

Skip Brake Fluid Changes For Years

Brake fluid is hygroscopic, gradually absorbing moisture that lowers its boiling point and corrodes brake lines and sensitive ABS valves. While fluid may appear clean, water content silently rises, which impacts stopping power during hard braking.

Alf van Beem, Wikimedia Commons

Alf van Beem, Wikimedia Commons

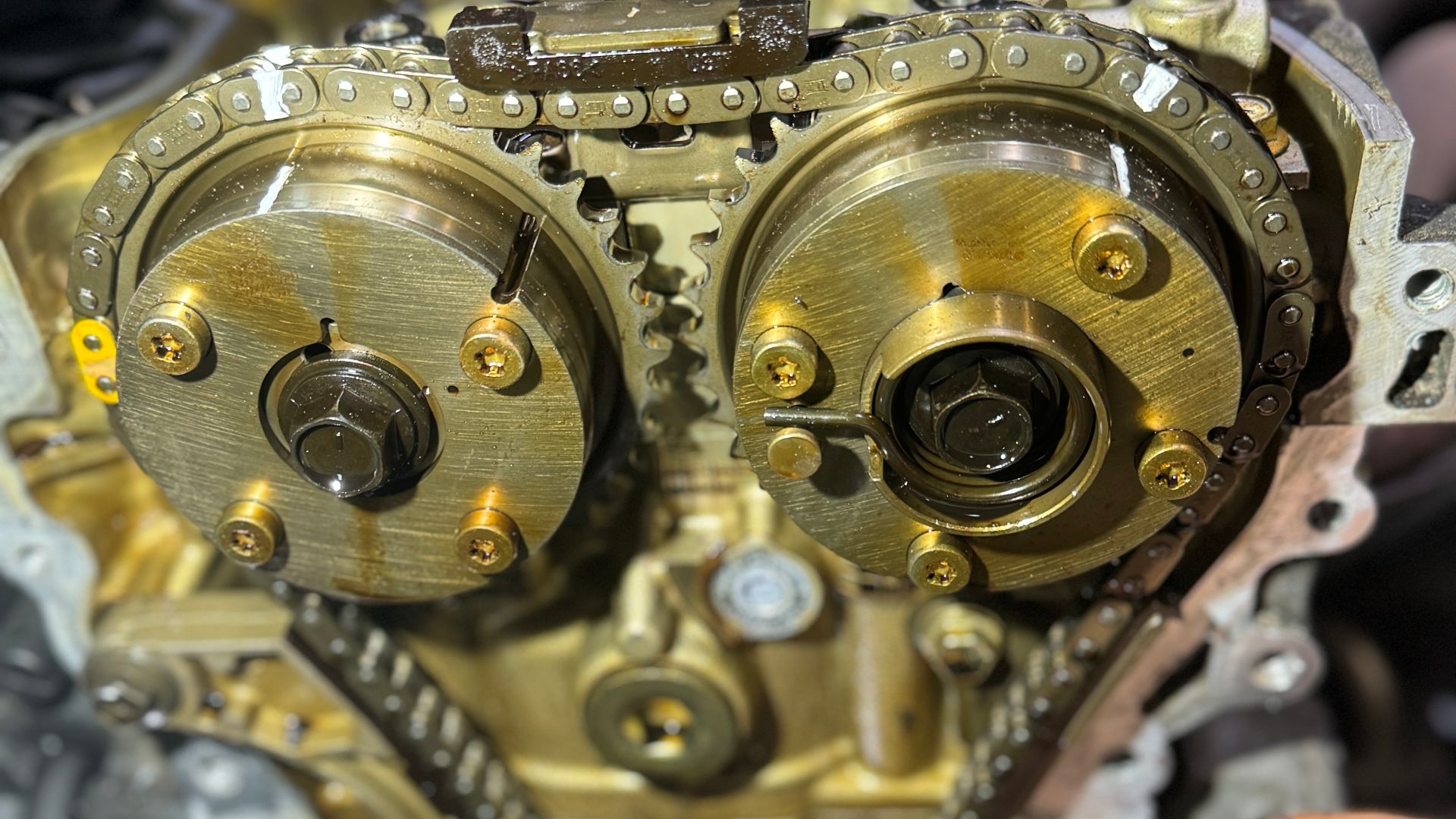

Ignore Timing Belt Or Chain Service When Due

Timing belts deteriorate over time, and stretched chains damage guides and tensioners, which risks catastrophic piston-to-valve contact in interference engines. Many failures occur without warning, leaving drivers stranded with severe internal damage.

Overtorque Or Impact-Gun Wheel Lug Nuts

Over-tightened lug nuts distort brake rotors and can cause uneven clamping forces that compromise wheel security. Professionals always start lug nuts by hand and use calibrated torque wrenches to meet manufacturer specifications. Proper installation preserves brake performance and reduces the risk of future failures.

Remove Lug Nuts with Impact Driver by JR Rustic

Remove Lug Nuts with Impact Driver by JR Rustic

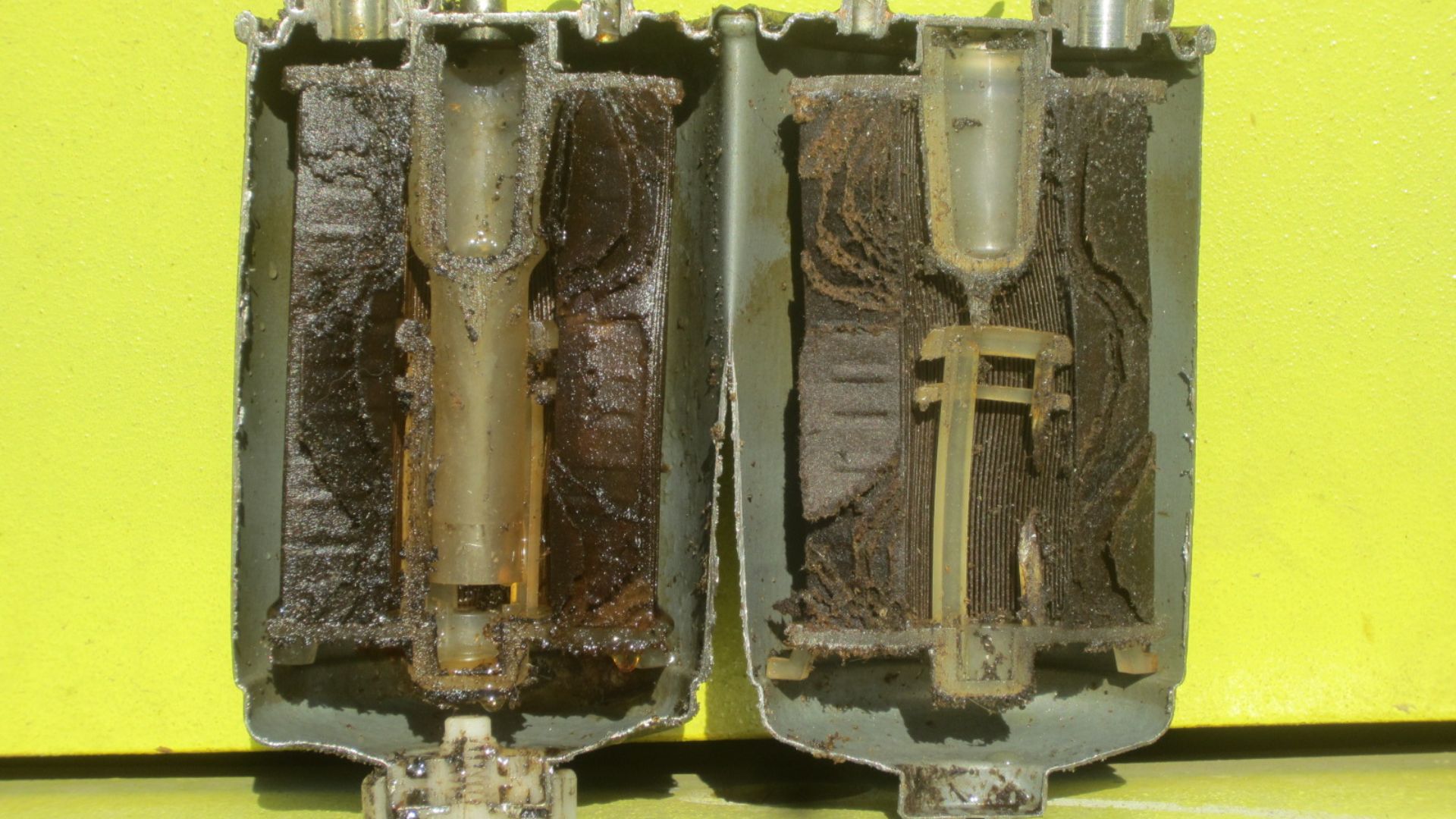

Cheap No-Name Oil Filters Or Extended Oil Intervals Without Evidence

Low-quality filters can bypass dirty oil or shed media, which accelerates wear on bearings and camshafts. Manufacturers design lubrication systems around specific flow and filtration targets. Exceeding intervals without testing invites sludge and varnish.

Harrikkamies, Wikimedia Commons

Harrikkamies, Wikimedia Commons

Run “Lifetime” Transmission Fluid Forever

Automatic transmissions generate heat that degrades additives and forms varnish on valves. Despite marketing, many “lifetime” fluids assume gentle duty and ideal temperatures. Towing or track use accelerates breakdown.

Use Stop-Leak Products As A Fix

Sealant particulates and swelling agents can clog heater cores or small oil passages, masking rather than resolving failures. They may contaminate sensors and complicate later repairs. Instead, technicians pressure-test systems and replace gaskets or components, then flush thoroughly to restore the designed flow.

How To Stop Radiator Leak with Permatex Radiator Stop Leak by Permatex

How To Stop Radiator Leak with Permatex Radiator Stop Leak by Permatex

Drive With A Glowing Oil Pressure Or Overheating Warning

Continuing to drive after oil-pressure loss or coolant overheat risks immediate engine damage: bearing seizure, warped heads, or cracked blocks. Warning lights signal critical conditions, not suggestions. Experienced technicians shut down, let temperatures stabilize, and arrange towing.

Install Mismatched Tire Sizes Or Loads On The Same Axle Or Mix Old And New On AWD

Different diameters or load ratings change rolling circumference and grip, confusing ABS and all-wheel-drive couplings. Mismatched tires can overheat differentials and produce unpredictable handling. Professionals match brand, model, size, and similar tread depth, rotating regularly.

HopsonRoad (Stephen Flanders), Wikimedia Commons

HopsonRoad (Stephen Flanders), Wikimedia Commons

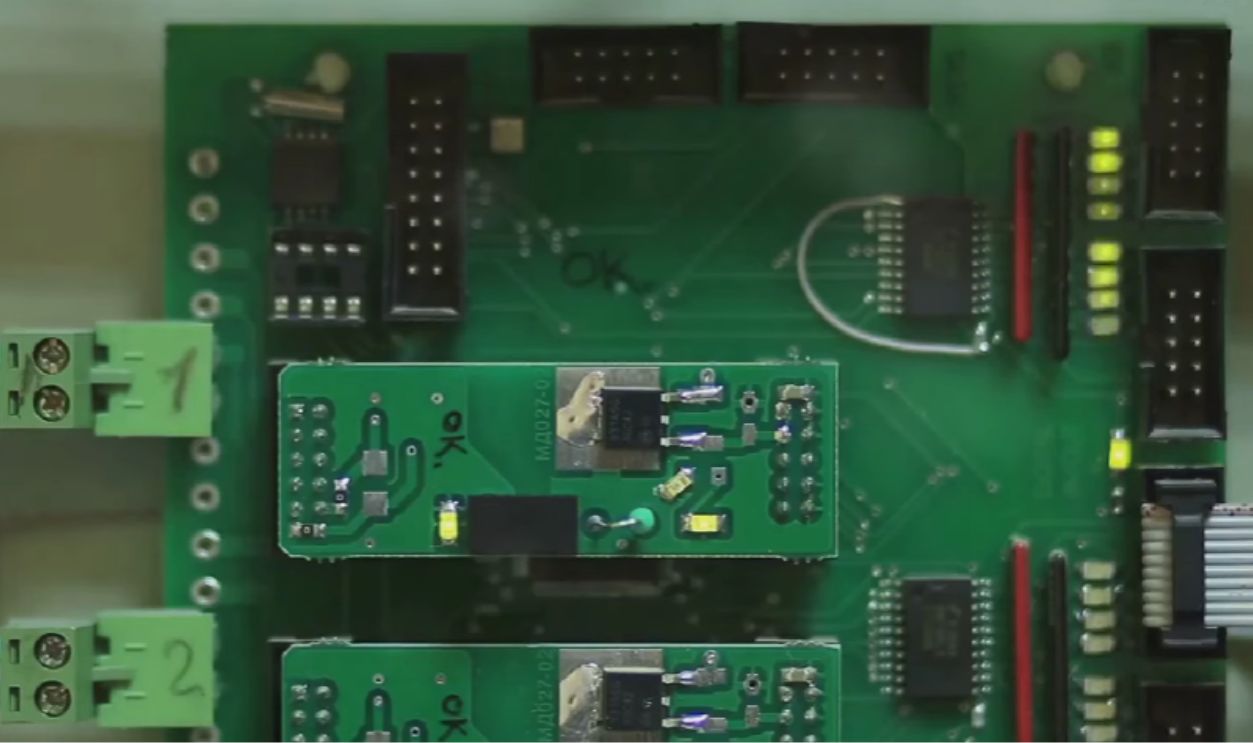

Jump-Start With Polarity Reversed Or “Spark It Anywhere”

Connecting jumper leads backward can instantly destroy diodes in alternators and damage engine control modules. Creating the final spark near a battery risks igniting hydrogen gas. Standard practice attaches positive to positive, negative to a solid engine ground, and disconnects in reverse order.

Symptoms of a Bad ECM (Engine Control Module Failure) by Honest Mechanic Colorado

Symptoms of a Bad ECM (Engine Control Module Failure) by Honest Mechanic Colorado

Use Ether Starting Fluid On Modern Gas Engines Routinely

Starting fluid’s volatility can wash cylinder walls, spike pressures, and trigger backfires that damage throttle bodies or airboxes. Many modern engines meter air precisely using MAF sensors and electronic throttles sensitive to harsh solvents. Rather than spraying, technicians verify fuel delivery, spark, coolant temperature inputs, compression, and crank sensors first.

SYMPTOMS OF BAD THROTTLE BODY ON A CAR by Auto Repair Guys

SYMPTOMS OF BAD THROTTLE BODY ON A CAR by Auto Repair Guys

Ignore Small Coolant Leaks And Keep Topping Off

Small leaks introduce air, creating steam pockets and hotspots that warp heads and degrade head gaskets. Repeated top-offs dilute additives and hide the root cause. Professionals pressure-test the system cold, inspect hoses, clamps, radiators, caps, and water pumps, then bleed per manufacturer procedure to restore stable temperatures.

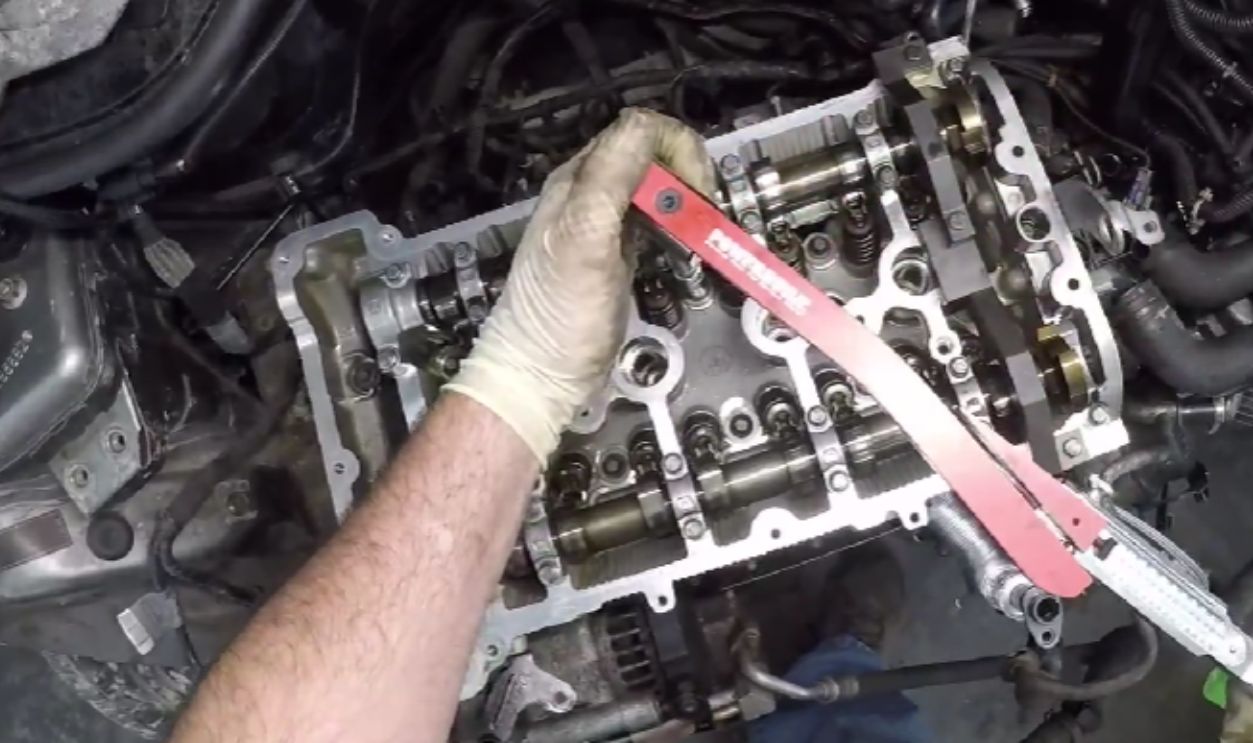

Torque-To-Yield Bolts Reused On Critical Components

Torque-to-yield bolts stretch plastically during installation to achieve clamping force. Reusing them reduces preload and risks sudden failure on critical joints like cylinder heads and some suspension components. Mechanics lubricate threads or use specified sealant and follow the angle-torque sequence precisely with calibrated tools.

Why Use Torque To Yield Bolts? by ETCG

Why Use Torque To Yield Bolts? by ETCG

Install Suspension Parts Without Alignment

After replacing tie rods or control arms, alignment angles shift, which causes edge wear and extra ABS or stability control intervention. Skipping alignment wastes new tires. Professionals set camber, caster, and toe to specifications and road-test to ensure confident highway stability.

“Clean” MAF Or Oxygen Sensors With Random Sprays

Mass airflow and oxygen sensors use delicate elements easily damaged by harsh solvents or residue. Generic cleaners and compressed air can ruin coatings or crack films, skewing fuel trims. Technicians use MAF-specific cleaner, avoid touching the element, check wiring and intake leaks, and replace sensors only when readings are out of range.

dave_7 from Lethbridge, Canada, Wikimedia Commons

dave_7 from Lethbridge, Canada, Wikimedia Commons

Overfill Crankcase Or Transmission

Overfilling engine oil or transmission fluid causes aeration and foam, reducing lubrication and creating erratic pressures. Excess levels can blow seals and contaminate catalytic converters via crankcase ventilation. Mechanics measure on level ground and recheck after warm operation to confirm the correct hot mark.

Use RTV Everywhere, Blocking Oil Or Coolant Passages

Excess RTV squeezes inside, forming silicone strings that detach and block oil pickups or coolant passages. Incorrect sealant also dissolves in fluids. Professionals clean mating surfaces, follow bead width diagrams, skip sealant where molded gaskets suffice, and allow proper cure time before adding fluids.

The only way to clean the oil pick up pipe by Twiggs T4

The only way to clean the oil pick up pipe by Twiggs T4

Ignore Fuel Filter And Run Near-Empty Routinely

Running near empty and stirred sediment can clog filters or injectors. Where serviceable, neglected filters increase pressure drop and reduce performance. Mechanics replace per schedule and advise keeping at least a quarter tank, especially during summer heat.

Install Bulbs/LEDs With Wrong Wattage Or Hacked Wiring

Overwatt bulbs overheat sockets and reflectors, melting housings and damaging switches. Mismatched LEDs can confuse CAN systems and trigger hyperflash or errors. Improvised taps invite shorts and fires. Mechanics match wattage and repair circuits with fuses and heat-shrink.

Bright bulbs, too hot. Melted fog light / headlight housing Genesis 4.6 sedan by Buckeye Ballistics

Bright bulbs, too hot. Melted fog light / headlight housing Genesis 4.6 sedan by Buckeye Ballistics

Use A Scissor Jack As A Stand Or Work Under A Car Without Proper Support

Scissor jacks are for roadside tire changes, not supporting crews beneath vehicles. Their bases and threads can shift or collapse. Shops lift on rated jacks, then place quality stands under solid points and shake-test stability.

Run Aggressive Tunes On Weak Fueling Or Cooling

High boost and advanced timing raise cylinder pressure and heat, demanding precise fueling and temperature control. Stock pumps, injectors, radiators, or intercoolers may fall short, inviting detonation and piston damage. Competent tuners upgrade hardware first and verify charge temperatures before chasing numbers on a dyno.

Wash The Engine Bay With High-Pressure Water Indiscriminately

Pressure washers force water past seals into alternators and junction boxes, creating corrosion and intermittent faults. Modern connectors are splash-resistant, not submersible. Professionals cover intakes, use low-pressure cleaners, agitate grime with brushes, and blow-dry carefully.

Ignore Differential Or Transfer Case Fluids

Axle gears and clutches depend on specified lubricants with correct viscosity and additives. Old fluid carries metal particles and moisture, which increases wear and overheating. Many trucks and crossovers require unique formulations.

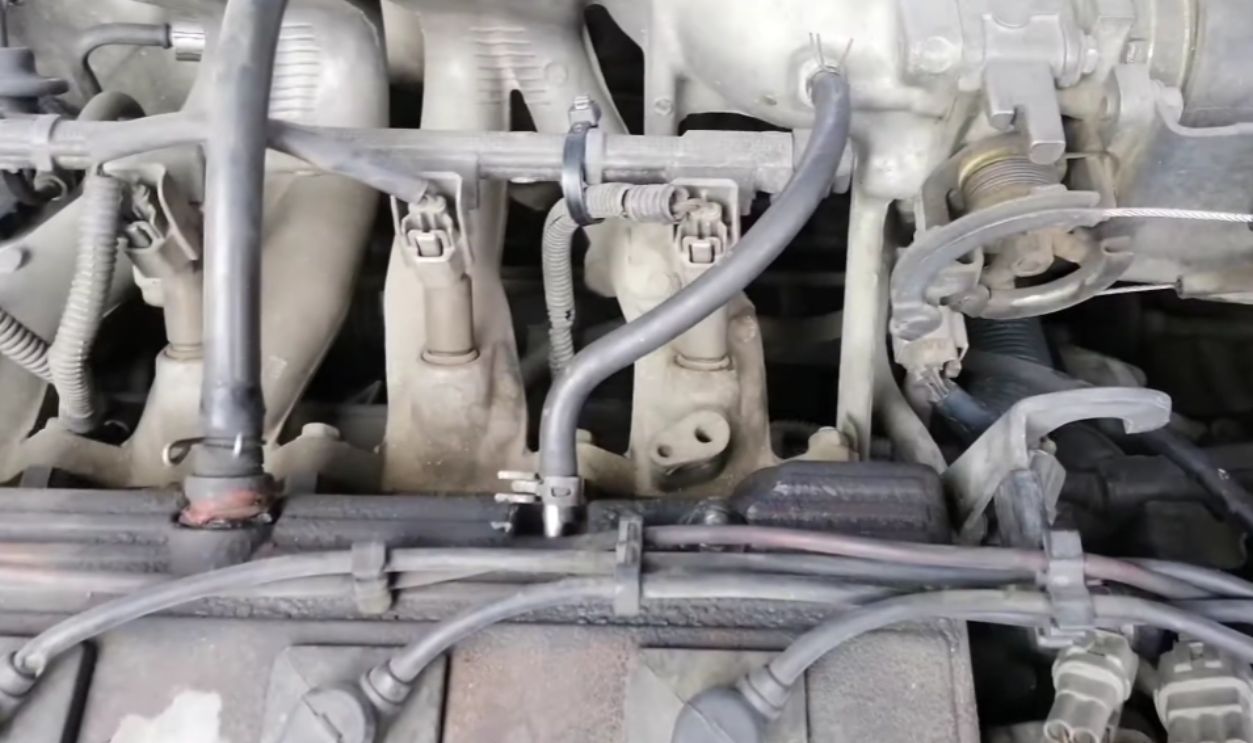

Keep Driving With Known Vacuum Or Intake Leaks

Unmetered air skews fuel trims, running cylinders lean and overheating valves or catalytic converters. Hissing or P0171 codes often follow. Rather than tolerate it, mechanics smoke-test the intake and replace cracked hoses or gaskets promptly.

Cheap and Quick DIY Engine Vacuum Hose Repair | TAGALOG by JM DIY

Cheap and Quick DIY Engine Vacuum Hose Repair | TAGALOG by JM DIY